Bulk Direct-to-Film (DTF) transfers are an efficient and cost-effective way to produce high-quality prints for apparel and other textiles. Whether you’re fulfilling large orders or looking to streamline your production process, this guide will cover everything you need to know about maximizing efficiency and cutting costs with DTF transfers bulk.

What Are Bulk DTF Transfers?

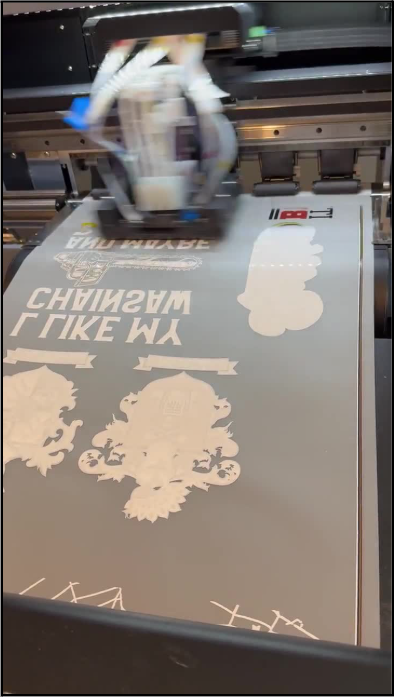

Bulk DTF transfers involve printing multiple designs on PET film at once, applying adhesive powder, curing the prints, and storing them for future application. Instead of printing and pressing one item at a time, you produce transfers in batches, which can be heat-applied on demand.

Benefits of Bulk DTF Transfers

- Time Efficiency

-

-

- Printing in bulk reduces setup time and minimizes repetitive steps.

- Stored transfers can be heat-applied quickly, saving time during order fulfillment.

-

- Cost Savings

-

-

- Bulk purchases of PET film, adhesive powder, and ink often come with discounts.

- Lower per-print labor costs due to streamlined workflows.

-

- Flexibility

-

-

- Pre-made transfers can be used for a variety of orders, eliminating the need to reprint designs.

-

- Reduced Waste

-

-

- Printing in batches allows for better material usage and fewer errors.

-

- Scalability

-

- Ideal for growing businesses handling high-volume orders.

Key Steps for Bulk DTF Transfer Production

1. Prepare Your Artwork

- Batch similar designs together on a single PET film to maximize space.

- Ensure designs are properly mirrored and sized for their intended use.

- Save designs in high-resolution formats (e.g., PNG, TIFF) to maintain print quality.

2. Optimize Your Printing Setup

-

- Use wide-format DTF printers for larger films to print more designs in a single pass.

- Calibrate your printer and RIP software to ensure consistent output.

-

- White Ink Layer: Uniform opacity for vibrant colors.

- Color Management: Accurate hues for every design.

3. Print on PET Film

- Choose high-quality PET film to ensure durability during storage and transfer.

- Print designs with white ink as the base layer, followed by CMYK colors.

4. Apply Adhesive Powder

- Spread adhesive powder evenly across the wet ink.

- Shake off excess powder to prevent clumps and uneven adhesion.

5. Cure the Transfers

- Cure in a curing oven or under a hover heat press at 165–170°C (330–340°F) for 2–3 minutes.

- Ensure the adhesive turns translucent, indicating it’s fully cured.

6. Store the Transfers

- Cut individual designs or store entire sheets.

- Keep transfers in a cool, dry environment, away from direct sunlight and moisture.

- Properly cured transfers can last 6–12 months when stored correctly.

7. Apply Transfers on Demand

- Use a heat press to transfer designs onto fabric:

- Temperature: 160–170°C (320–340°F)

- Time: 15–20 seconds

- Pressure: Medium to high

- Peel cold for the best results.

Tips to Save Time and Money in Bulk DTF Transfers

1. Use Wide-Format Printers

- Invest in a wide-format DTF printer to maximize the number of designs printed per film roll.

2. Buy Supplies in Bulk

- Purchase PET film, adhesive powder, and inks in large quantities to benefit from volume discounts.

3. Standardize Designs

- Create popular designs that can be printed and stored in large quantities for repeated use.

4. Automate Where Possible

- Use automated curing ovens and powder shakers to speed up production and ensure consistent results.

5. Reduce Errors

- Double-check designs and printer settings before printing to avoid costly mistakes.

- Perform regular maintenance on printers to prevent downtime.

Calculating Costs for Bulk DTF Transfers

To determine your cost savings, consider:

- Material Costs: PET film, ink, adhesive powder.

- Labor Costs: Time spent printing, curing, and pressing.

- Equipment Costs: Amortized over production runs.

- Storage Costs: Space and conditions for storing pre-made transfers.

For example:

- Cost per transfer may decrease significantly when printing 500 designs at once versus printing individual designs, as setup and material wastage are reduced.

Common Challenges and Solutions

1. Adhesive Powder Clumping

- Solution: Store powder in a dry place and ensure even application.

2. Ink Smudging During Bulk Printing

- Solution: Allow sufficient drying time between printing and powder application.

3. Difficulty in Storage

- Solution: Use flat storage folders or hanging racks to keep transfers organized and undamaged.

4. Inconsistent White Ink Layer

- Solution: Regularly shake white ink and maintain printhead cleanliness.

Applications for Bulk DTF Transfers

- Merchandise Production

-

-

- T-shirts, hoodies, tote bags, and caps for events or brands.

-

- Custom Orders

-

-

- On-demand printing for personalized designs.

-

- Wholesale Transfers

- Selling pre-made transfers to other businesses or individuals.

Conclusion

Bulk DTF transfers are a powerful way to save time and money while scaling your business. By investing in the right equipment, optimizing your processes, and managing inventory effectively, you can produce vibrant, high-quality designs at a fraction of the cost. Whether you’re fulfilling large orders or preparing for busy seasons, bulk DTF printing ensures you’re ready to meet demand with ease.