Precision is the first in modern production. Every detail matters, particularly with the equipment shaping, sharpening, and perfecting cutting instruments. Central to this accuracy is the wheel dressing machine maker, a key player guaranteeing the lifetime and best performance of grinding wheels. These companies create creative tools restoring worn wheels to their former shape and condition, hence improving accuracy and consistency over a broad spectrum of industrial uses. Their technology-driven solutions let manufacturers and workshops increase production, cut waste, and attain perfect surface finishes with the least downtime.

The Power and Precision of a Diamond Wheel Dressing Tool

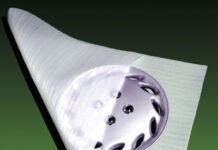

Handling super abrasive wheels like diamond or CBN calls for sophisticated dressing technologies even more important. Designed primarily to true and dress diamond grinding wheels, a diamond wheel dressing machine provides unrivalled hardness and wear resistance. Important for sectors like aerospace, automotive, and medical device manufacture, these machines can precisely execute complicated dressing profiles. Their automated control systems and high-speed spindles provide effective material removal and prolonged tool life, hence ensuring their vital value in places where accuracy is non-negotiable.

Innovation in Dressing Technologies Drives Performance

Technological developments have changed how companies preserve and renew their grinding wheels. Today’s machines include smart technologies like adaptive algorithms that fine-tune the dressing process, real-time feedback loops, and CNC controllers. Apart from increasing the efficiency of wheel maintenance, these developments also improve the repeatability of production results. Manufacturers are providing equipment that is quicker, smarter, and more ecologically friendly by merging modern engineering with traditional workmanship. Consequently, companies run cheaper and have better component quality, remaining competitive in a globalized market that expects perfection.

Customized Solutions for Industry-Specific Requirements

Different industries need various dressing solutions, and machine makers have stepped up with adjustable systems. Specialized dressing machines can be set for precise uses, whether they are producing ultra-fine edges for medical instruments or preserving forceful profiles for heavy gear. These customized solutions consider the kind of grinding wheel, the material being machined, and the required final quality. Companies can now pick equipment from standalone models to completely integrated production line systems that exactly fit their objectives, production quantities, and technical criteria.

Modern Machine Design: Efficiency and Sustainability

Sustainability is now a need, not a catchphrase. Manufacturers of dressing machines are designing energy-efficient models that minimize coolant usage, reduce power consumption, and increase the life cycle of both wheels and tools. Incorporating environmentally friendly policies into machine design helps to support world initiatives to cut industrial waste and carbon footprints. Furthermore, automated solutions cut the requirement for human intervention, hence lowering labour expenses and occupational risks. This harmony of commercial and environmental objectives shows how contemporary machines can assist both profitability and planetary well-being.

Unmatched After-Sales Services and Support

A dependable machine is only one component of the equation. Leading manufacturers know how crucial support services are; they provide training, maintenance, and quick-response troubleshooting to optimize uptime. Their dedication to consumer happiness spans the whole life of the equipment, not only at the point of sale. Clients can get professional advice on maximizing machine settings, identifying performance problems, and including new technology in current processes with the correct partner. This all-encompassing assistance guarantees ongoing development and operational excellence, hence building long-term relationships founded on trust and mutual success.

Conclusion

Maintaining grinding wheel integrity is absolutely crucial in modern high-precision sectors. Investing in the appropriate dressing machines gives companies a clear advantage in quality, performance, and efficiency. Whether via a committed wheel dressing machine manufacturer or the application of a high-performance diamond wheel dressing machine, companies are enabled to attain new degrees of manufacturing perfection. Consider looking at top-tier solutions at proemachinery.com if you want to improve your production operations with innovative, dependable, sustainable technology. Your workshop can thrive at every grind with the correct tools and knowledge.