The demand for durable and precise rubber components in various industries has surged over the years. Among the many essential elements, OEM rubber gasket moldings and rubber window channels stand out for their role in providing reliable seals and insulation for windows, doors, and other mechanical systems. These components ensure a tight fit, preventing leakage and offering protection from environmental factors like dust, water, and noise. Manufacturing these components requires specialized expertise, making it essential to choose the right supplier to ensure quality and reliability in the final product.

What Makes an OEM Rubber Gasket Moldings Manufacturer Stand Out?

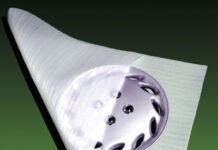

An OEM (Original Equipment Manufacturer) rubber gasket molding supplier is a key player in providing custom-made seals for various applications, including automotive, construction, and industrial machinery. The primary role of an OEM rubber gasket moldings manufacturer is to produce high-quality, durable rubber seals that fit the unique specifications of each product. They use advanced techniques, such as compression molding, injection molding, and extrusion, to ensure the precision and quality of every gasket. The manufacturer’s ability to work with different rubber compounds and mold shapes is crucial to meeting the diverse needs of its clients, offering flexibility in design and functionality.

Rubber Window Channels: Key Applications and Benefits

Rubber window channels are a critical component in automotive, residential, and commercial window systems. They function by providing a secure and protective frame for the glass, ensuring proper alignment and reducing vibrations. As a result, these rubber channels contribute to energy efficiency, noise reduction, and enhanced durability of window systems. The flexibility and resistance of rubber make it an ideal material for these applications, and working with a reliable rubber window channels munufacturer ensures that these products are made to withstand weathering, wear, and constant movement without losing their effectiveness.

How to Choose the Right OEM Rubber Gasket Moldings Manufacturer

When selecting an OEM rubber gasket moldings manufacturer, it is essential to evaluate several factors to ensure the highest quality product. First, consider the manufacturer’s experience and reputation in the industry. Established companies are more likely to use state-of-the-art technology and high-grade materials, guaranteeing precision and durability. Additionally, reviewing the manufacturer’s quality control processes is crucial to ensure the production of defect-free gasket moldings. A reputable manufacturer will provide testing services and meet strict industry standards, ensuring that their products deliver long-term performance and reliability for critical applications.

The Importance of Selecting a Trusted Rubber Window Channels Manufacturer

Choosing the right rubber window channel manufacturer is equally important to ensure that the product meets all required standards for quality, durability, and performance. A reliable manufacturer will provide custom solutions to fit specific window designs, offering both functional and aesthetic benefits. The ability to source high-quality rubber compounds that are resistant to UV rays, moisture, and extreme temperatures is vital for the longevity of the rubber window channels. Additionally, look for manufacturers with proven experience in the window and glazing industries, as their expertise will ensure the optimal performance of your window seals in various conditions.

Conclusion

In conclusion, whether you are seeking OEM rubber gasket moldings or rubber window channels, selecting the right manufacturer is key to achieving high-performance, durable, and reliable products. By choosing an experienced and reputable manufacturer, you ensure that these rubber components are tailored to your exact needs, whether for automotive, construction, or any other application. The combination of quality materials, advanced manufacturing processes, and stringent quality control standards will result in products that meet or exceed industry standards, ensuring that your rubber components provide lasting value and performance.